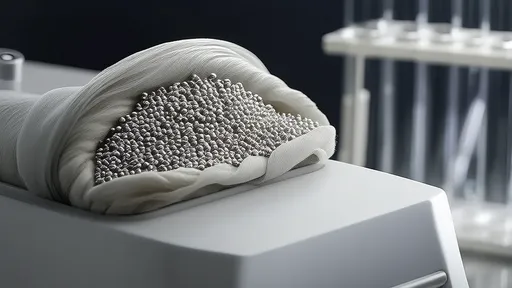

In the world of textile preservation, vacuum compression has emerged as a popular space-saving solution for seasonal clothing storage. However, many fashion enthusiasts and collectors worry about potential damage to delicate fabrics when using this method. The science behind proper vacuum compression reveals that when done correctly, this technique can effectively protect garments without compromising their integrity.

The key lies in understanding fabric composition and compression limits. Natural fibers like wool, silk, and cotton require different handling compared to synthetic blends. Wool garments, for instance, possess natural elasticity that allows them to bounce back after compression, provided they're given adequate recovery time. Silk, while more delicate, can withstand gentle vacuuming if properly layered with acid-free tissue paper to prevent creasing in permanent folds.

Modern vacuum storage systems have evolved significantly from the early models that often caused pressure-related damage. Contemporary compression bags feature adjustable pressure settings and breathable membranes that maintain fabric health. These technological advancements allow for gradual air removal rather than the harsh suction that once led to fiber stress and deformation.

Pre-treatment before compression plays a crucial role in fabric preservation. Garments must be impeccably clean before storage, as any residual body oils or stains can set permanently under pressure and accelerate fabric degradation. Professional conservators recommend a thorough inspection for pests and complete drying to prevent mildew formation in the oxygen-reduced environment.

The duration of compression significantly impacts fabric wellbeing. While vacuum storage works well for seasonal rotation (typically 3-6 months), extended compression beyond a year may cause permanent creasing in certain fabrics. For heirloom pieces or couture garments, experts suggest alternative preservation methods that don't involve sustained pressure.

Temperature control during compressed storage often gets overlooked. Storing vacuum bags in climate-controlled environments prevents the temperature fluctuations that can weaken fibers under pressure. Ideal conditions mirror museum standards: stable temperatures around 65°F (18°C) with 45-55% relative humidity, even within compressed formats.

Layering techniques within vacuum bags create micro-environments that protect delicate surfaces. Placing heavier items at the bottom and using cotton muslin as separator sheets prevents embellishments from imprinting on adjacent fabrics. This method proves particularly valuable for preserving beaded gowns or embroidered textiles that might otherwise suffer from direct pressure.

The decompression process requires as much attention as the packing stage. When removing garments from long-term vacuum storage, allowing 24-48 hours for gradual re-expansion helps fibers regain their natural alignment. Professional conservators often use specialized steamers at controlled distances to help fabrics recover their drape without subjecting them to harsh stretching.

Innovative materials in vacuum storage technology continue to improve fabric safety. Recent developments include compression bags with built-in pH buffers to prevent acid migration and antimicrobial linings that inhibit microbial growth in the oxygen-deprived environment. These advancements make vacuum storage increasingly viable for delicate and vintage textiles.

Understanding these scientific principles allows fashion archivists and everyday users alike to harness the space-saving benefits of vacuum compression without sacrificing garment longevity. As textile science progresses, the gap between convenient storage and museum-quality preservation continues to narrow, offering new possibilities for maintaining extensive wardrobes in limited spaces.

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025