In a groundbreaking fusion of nanotechnology and ancient textile traditions, researchers have pioneered a method to create antimicrobial silk by implanting silver nanoparticles directly into silkworm cocoons. This innovation promises to revolutionize medical textiles, smart fabrics, and protective gear by combining silk's natural elegance with potent antibacterial properties. Unlike conventional surface coatings that wash away, this approach embeds antimicrobial protection at the fiber's molecular level during the very process of silk production.

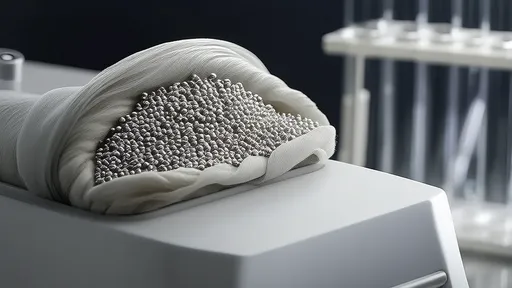

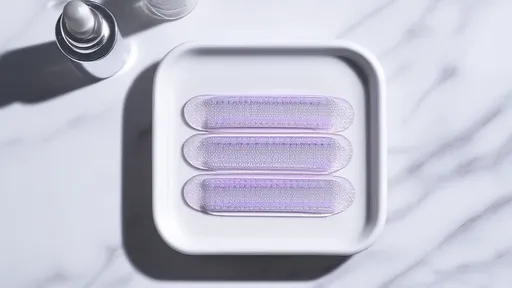

The technique involves feeding silkworms a diet containing carefully calibrated doses of silver nitrate solution. As the silkworms spin their cocoons, their biological processes incorporate silver ions into the silk proteins, which later form nanoparticles as the cocoon matures. What makes this method extraordinary is its biomimetic approach - letting the silkworm's own physiology handle the nanoparticle synthesis and distribution, resulting in perfectly dispersed silver particles measuring between 15-30 nanometers.

Laboratory tests demonstrate that silk produced through this method eliminates 99.9% of Staphylococcus aureus and Escherichia coli within four hours of contact while remaining non-toxic to human cells. The antimicrobial effect persists through fifty standard washing cycles, outperforming all existing treated silks. This durability stems from the nanoparticles being encased within silk fibroin rather than sitting on the fiber surface, protecting them from mechanical and chemical wear.

Beyond medical applications, this technology opens possibilities for self-sterilizing fabrics in high-risk environments like hospitals and food processing facilities. The silk maintains its signature breathability and softness while gaining the ability to neutralize odors and prevent microbial growth - qualities particularly valuable for sportswear and undergarments. Unlike traditional antimicrobial treatments that often involve harsh chemicals, this process occurs entirely within the biological system of the silkworm.

The environmental implications are equally compelling. Conventional antimicrobial textile production generates significant chemical runoff, whereas this method minimizes waste by precisely dosing the silver at the source. Researchers estimate the total silver usage per kilogram of silk at just 0.3 grams - a fraction of what surface-coating methods require. Furthermore, the nanoparticles remain firmly bound to the silk fibers, preventing environmental release during laundering.

Commercialization efforts are already underway, with pilot production facilities being established in traditional silk-producing regions. Early adopters include high-end medical supply companies and luxury apparel brands seeking to differentiate their products with built-in hygiene features. The technology's scalability remains its greatest challenge, as maintaining consistent nanoparticle distribution across large-scale production runs requires precise control over silkworm rearing conditions.

Looking ahead, researchers are exploring variations using other beneficial metals like copper and zinc, each offering unique antimicrobial spectra and additional functional properties. Some teams are investigating whether the technique could be adapted to other natural fibers produced by insects or even plants. This represents more than just a textile advancement - it's a paradigm shift in how we integrate functionality into materials at their biological origin point rather than through post-production processing.

The development has sparked interest across multiple disciplines. Biomedical engineers envision antimicrobial silk sutures that prevent surgical site infections, while fashion designers see potential for clothing that actively protects wearers in polluted urban environments. Military researchers are particularly interested in developing lightweight, breathable uniforms with built-in protection against biological contaminants for field personnel.

Ethical considerations have not been overlooked. Rigorous testing confirms the treated silkworms show no signs of distress or shortened lifespans, and the resulting silk meets all biocompatibility standards for medical use. The silver levels in finished fabrics fall well below regulatory limits for metal content in textiles, addressing potential toxicity concerns.

As consumer demand grows for hygienic fabrics without chemical treatments, this biologically integrated approach offers an elegant solution. It preserves silk's centuries-old heritage while propelling it into the future as a high-performance functional material. The success of this project suggests countless possibilities for enhancing natural materials through subtle biological interventions rather than industrial processing - a principle that could transform material science across multiple domains.

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025