The world of footwear is undergoing a quiet revolution, and it's happening right beneath our feet. At the intersection of 3D printing technology and podiatric science, a new generation of customized arch support slippers is emerging to address one of humanity's most common yet overlooked physical ailments - improper foot alignment. These pressure-balancing slippers aren't just another wellness gimmick; they represent a fundamental shift in how we approach foot health at home.

Traditional slippers have remained largely unchanged for decades - flat, flimsy, and offering about as much support as walking barefoot on concrete. Meanwhile, the average person takes between 4,000 to 6,000 steps per day inside their home, often wearing footwear that does nothing to prevent the gradual collapse of arches or the uneven distribution of pressure across the plantar surface. This daily neglect manifests in ways most people don't immediately connect to their feet: knee pain, hip misalignment, even chronic lower back issues.

The science behind pressure-balanced slippers begins with understanding how feet naturally support the body's weight. A healthy foot distributes pressure across three main points: the heel, the base of the big toe, and the base of the little toe, with the arch acting as a shock-absorbing spring. When this system fails due to flat feet, high arches, or other biomechanical issues, certain areas become overloaded while others barely touch the ground. Custom 3D printed arch supports work by precisely compensating for these imbalances, creating an artificial structure that mimics how an ideal foot should function.

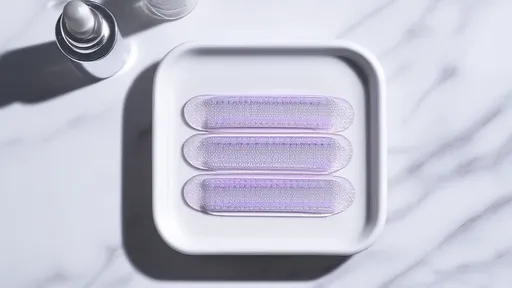

What makes the new generation of slippers truly revolutionary isn't just their supportive qualities, but how they're created. Using advanced foot scanning technology - sometimes as simple as taking photos with a smartphone app - manufacturers can now generate a three-dimensional map of a customer's unique foot topography. This data drives a 3D printer to build up layers of specialized polymers that cradle every curve and contour of the individual's arch structure. The materials used often combine flexibility with firm support, allowing for natural foot movement while preventing harmful overpronation or supination.

The customization goes beyond just arch height. Sophisticated algorithms analyze pressure distribution patterns to determine exactly where each foot needs more or less material. Someone who tends to put more weight on their inner foot might receive a denser medial post, while another person whose weight shifts outward would get reinforcement along the lateral side. This level of personalization was unimaginable in mass-produced footwear even five years ago, but 3D printing makes it not only possible but increasingly affordable.

For people with existing foot conditions like plantar fasciitis or bunions, the benefits can be life-changing. The constant micro-adjustments our bodies make to compensate for poor support create tension throughout the kinetic chain. By providing proper alignment starting at ground level, these slippers can reduce strain on ankles, knees, and hips. Many users report decreased pain after just a few days of wearing their custom slippers around the house, especially those who spend significant time standing on hard surfaces.

The environmental impact of this approach shouldn't be overlooked either. Traditional orthotics often involve multiple fitting appointments, plaster casts, and significant material waste. 3D printing generates almost no waste material, as the additive manufacturing process only uses what's needed. When the slippers eventually wear out, many of the materials can be recycled into new pairs, creating a more sustainable model for foot care products.

As the technology matures, we're seeing innovations in the slippers themselves. Some companies are experimenting with responsive materials that stiffen under pressure and soften when at rest, effectively creating a dynamic support system that adjusts throughout the day. Others are incorporating temperature regulation or antimicrobial properties directly into the printed material. The humble house slippers is evolving into a sophisticated biomechanical device, all while maintaining the comfort and convenience people expect from their indoor footwear.

This movement toward customized foot health isn't just about treating problems - it's about prevention. Children could grow up with slippers that support their developing arches properly, potentially avoiding many common foot issues before they start. Office workers might keep a pair under their desk to switch out of dress shoes. The elderly could benefit from slippers that compensate for age-related changes in foot structure while preventing slips and falls.

The market response has been telling. What began as niche products through podiatrist referrals have exploded into direct-to-consumer offerings with month-long waiting lists. As production scales and prices continue to drop, pressure-balancing slippers may soon become as commonplace as memory foam mattresses or ergonomic office chairs - products we now consider essential for daily wellbeing that were once considered luxury items.

Looking ahead, the implications extend beyond just slippers. The same scanning and printing technology could revolutionize all types of footwear, from running shoes to work boots. Some forward-thinking companies are already exploring ways to integrate this customization into stylish designs that don't sacrifice aesthetics for functionality. The line between medical device and fashion accessory is blurring, and our feet will be better for it.

In many ways, the story of 3D printed arch support slippers mirrors larger trends in personalized healthcare and sustainable manufacturing. It represents a convergence of technologies that allow for solutions tailored to individual bodies rather than forcing bodies to conform to mass-produced solutions. As awareness grows about how foundational foot health is to overall wellbeing, these slippers may well become the standard rather than the exception in households worldwide.

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025