The world of classic car restoration is undergoing a quiet revolution, one layer of thermoplastic at a time. For decades, enthusiasts and professional restorers alike have faced the same frustrating problem: original parts for vintage vehicles are either impossible to find or prohibitively expensive. Now, a growing movement is embracing 3D printing technology to breathe new life into automotive history.

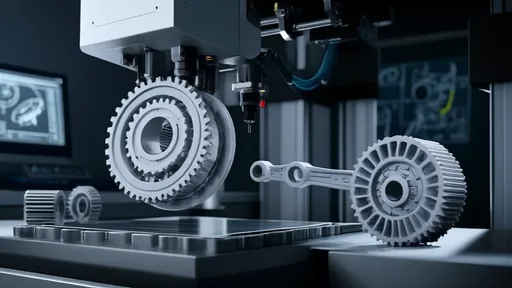

Walk into any serious restoration shop today, and you'll likely find a 3D printer humming away in the corner. What began as a niche solution for unobtainable trim pieces has evolved into a full-fledged alternative for manufacturing complex mechanical components. The technology has reached a point where printed parts can match or even exceed the quality of original factory components, while remaining faithful to the vehicle's heritage.

Consider the case of a 1957 Chevy Bel Air door handle. Original units in good condition might fetch hundreds of dollars at swap meets, if you can find them at all. With 3D scanning and printing, restorers can now reproduce the handle with perfect accuracy, using materials that resist corrosion better than the pot metal originals. This isn't just about convenience—it's about preserving automotive history for future generations.

The process typically begins with meticulous digital capture of existing components. Even when working with damaged or incomplete parts, modern software allows engineers to reconstruct missing elements based on symmetry, known dimensions, or archival photographs. This digital resurrection often reveals details that have been lost to time, enabling recreations that are more authentic than aftermarket reproductions made through traditional methods.

Material science has been crucial to this advancement. Early adopters struggled with plastics that couldn't withstand engine heat or UV exposure. Today's high-performance filaments and resins mimic the properties of metal, rubber, and glass. Some shops even employ metal printers that lay down powdered alloys layer by layer, creating fully functional engine components that meet or exceed original specifications.

Purists initially dismissed 3D printing as cheating, but the reality has proven more nuanced. The best restoration shops use printing as one tool among many, combining it with traditional metalworking and upholstery techniques. A printed part might serve as a pattern for casting, or as a temporary stand-in while hunting for an original. In many cases, the printed version becomes the permanent solution because it simply works better.

Legal and ethical considerations continue to evolve alongside the technology. Intellectual property rights surrounding classic car designs remain murky, particularly for defunct manufacturers. Most restoration communities have adopted an honor system—printing parts for personal use is generally accepted, while commercial reproduction sparks debate. Some enterprising shops have begun working directly with classic car clubs to establish guidelines for acceptable practices.

The environmental impact presents another compelling advantage. Traditional reproduction methods often involve energy-intensive processes and generate substantial waste. 3D printing's additive manufacturing approach uses only the material needed for the part, with minimal scrap. For rare vehicles where original parts would otherwise be cannibalized from donor cars, printing offers a more sustainable path to preservation.

Looking ahead, the implications extend beyond restoration. 3D printing is enabling entirely new approaches to classic car customization and performance upgrades. Enthusiasts can now design and test modified components without the tooling costs that once made such experimentation impractical. A vintage sports car might receive a discreetly upgraded intake manifold that looks stock but flows better, all thanks to printed prototypes that accelerated development.

As the technology continues advancing, we're seeing the emergence of complete digital archives for certain models—every nut, bolt, and bezel preserved as printable files. These repositories serve as insurance against the ravages of time, ensuring that even as original parts continue to degrade or disappear, the knowledge required to recreate them remains accessible. In this way, 3D printing isn't just changing how we restore old cars—it's changing how we think about preserving automotive heritage altogether.

The romance of classic cars has always lain in their mechanical authenticity, the tangible connection to automotive history. Ironically, the very digital technology that threatens to make modern cars feel disposable may become the key to keeping our automotive past alive. In workshops around the world, the whir of a 3D printer has become the sound of history being rewritten, one precise layer at a time.

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025